Hardener

-

Min Order

1

-

Product Unit

Pieces

-

Origin

China Mainland

-

Payment

- Contact Now Start Order

- Favorites Share

- Description

Product Detail

Water Transfer Printing Hardener

| Type | Hardener |

| Packing KG | 25L 180L |

| MOQ | 180L |

| Delivery Time | Within 3 working days |

| Payment terms | 100% payment by T/T advance or western union |

| Material | Hardener |

| Features | Water Soluble Abrasion Resistancecan be degraded by bacteria and enzymes 100% |

| Blank Film of Origin | Japan Import |

| Water Temperature | 25- 35 |

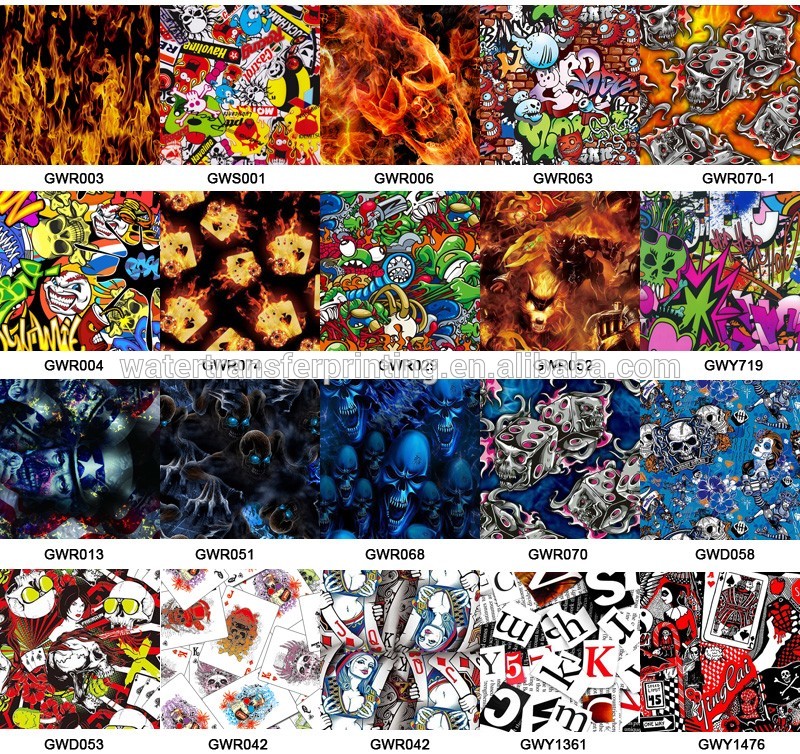

Rolyaty Patterns

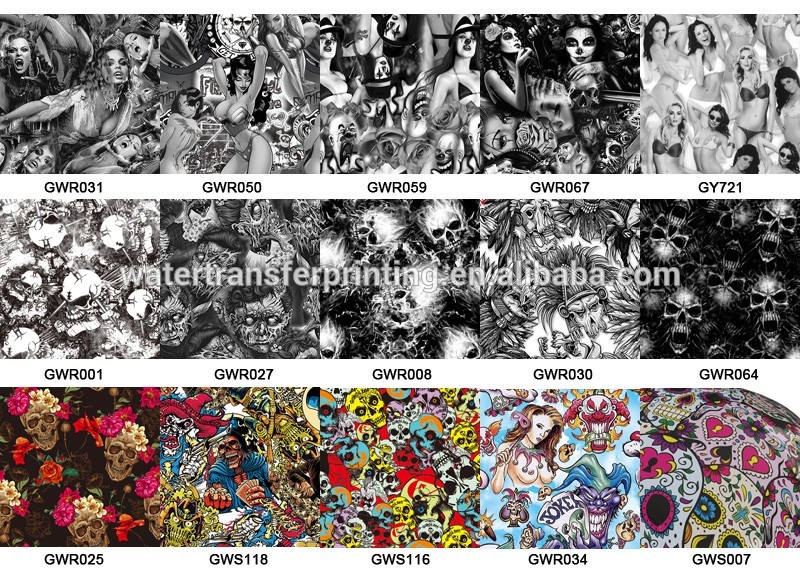

Skull Patterns

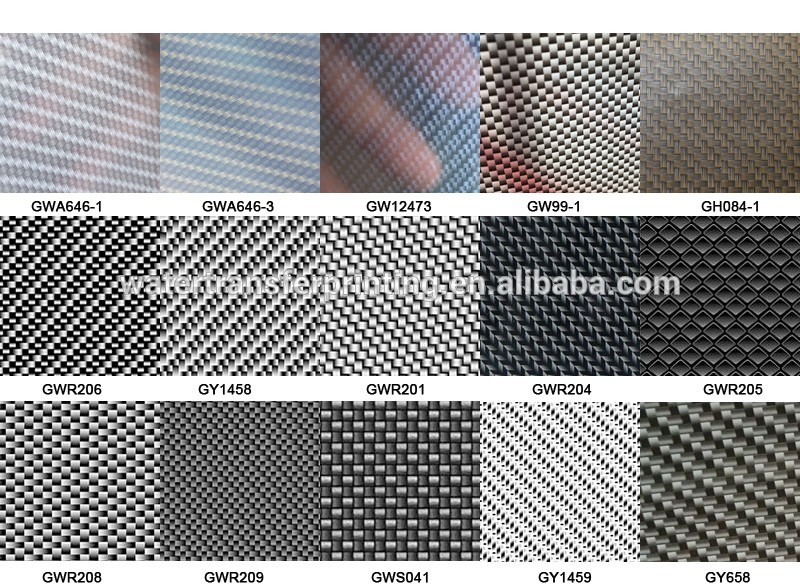

Carbon Fiber

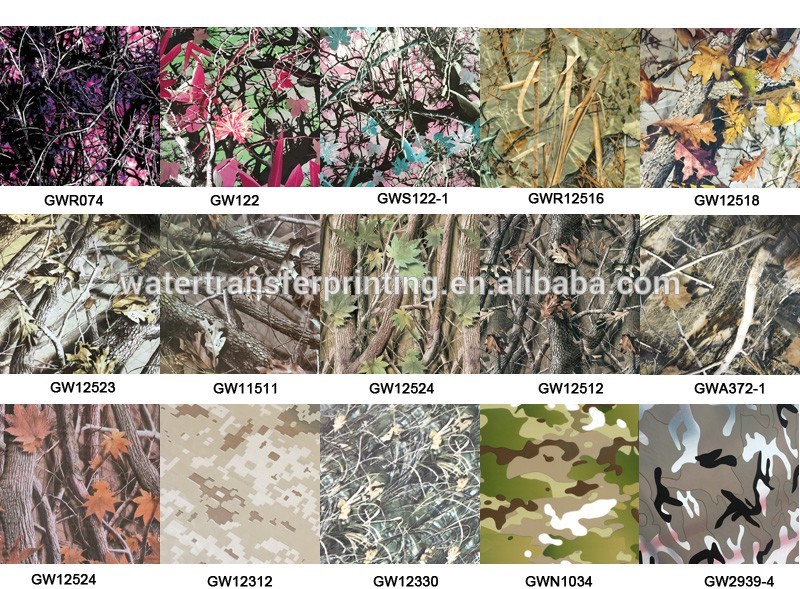

Camouflage Pattern

Wood Patterns

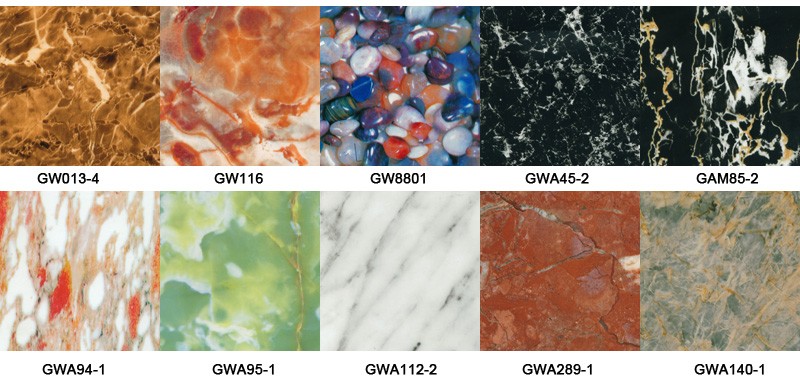

Marble&Stone Pattern

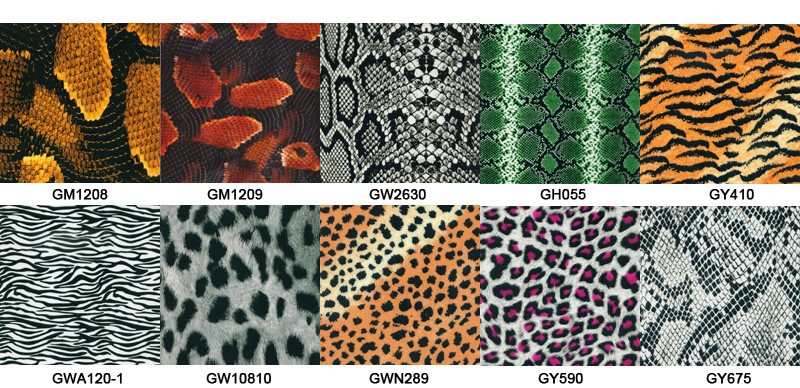

Animal Skin Patterns

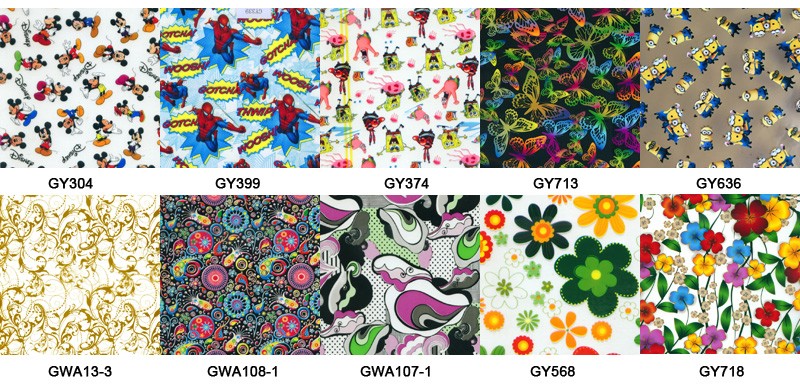

Flowers patterns

Frequently Asked Questions

1)What is the cost?

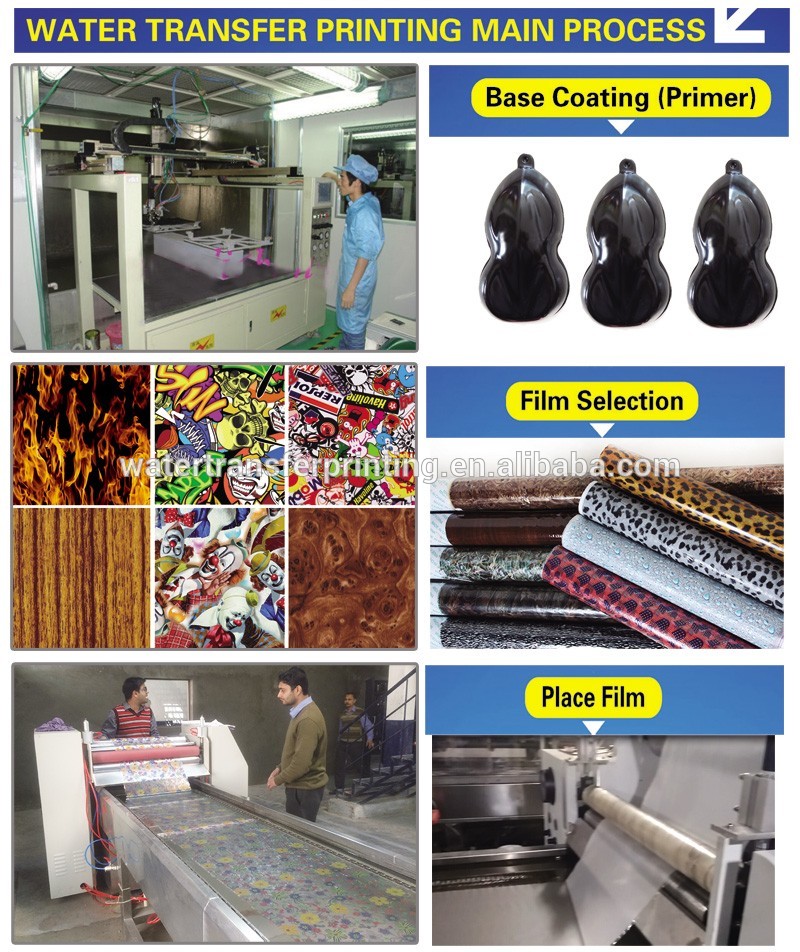

Water Transfer Printing is economical and advancedcost-effective process,which faced problem by traditional printing methods such as hot printing, screen printing, transfer printing, and conversion coating.

2)Is Water Transfer Printing durable?

We like to let our product speak for itself. Some of our largest clientele are automobile and boat manufacturers who demand highest standards of quality and durability. Many parts we manufacture spend the majority of their lives in direct exposure, such as boat instrument panels. The clear coat we use is automotive grade, designed to withstand nature and time.

3)How difficult is it to learn the process?

24-hours of training,it takes an additional period of two to three weeks to fine-tune the production line.

4)Can items that are not correctly printed be reprinted?

Yes, items that are not printed to satisfaction can be re-printed for printing.The decorated piece needs to be sanded and painted again .After that,the piece will be ready again for printing process.

5)What types of items can be printed?

A wide variety of flat or 3-D shapes (curved and bend surface) and manufacturing materials (plastics, metals, etc.) can be printed.

6)How scratch-resistant is the final product?

The clear acrylic topcoat recommended is the same as that used on auto exteriors.The clear coat is a very important step of the process. It protects the items from scratching and gives them durability

7)How should I set up my Water Transfer Printing facility?

Before setting up your production plant, many things need to be considered. Size of items to be printed and amount of items to be printed are the most important. After answering these two questions you will know the approximate space needed to accommodate fixtures, hydrographic films and equipment. Please check our Equipment film catalogue on www.greaterwindgroup.com.

8)How much power do I need to set up a Water Transfer Printing facility?

In order to determine how much power is needed for the selected equipment, we invite you to visit our Equipment specific documentation on website

What are all the machine and components needed to successfully produce a decorated item?

The essential components are:

a. The hydrographic film with selected design/pattern,

b. Activator,

c. A hand sanding device,

d. A spray gun and air compressor,

e. Primer, the selected base coat paint, and clear acrylic paint,

f. The specifically designed machine such as, spray booth ,automatic /manual dipping machine ,washing machine convey/ water rinse station ,drying oven tunnel.

g. A device to hold the item while it is being dipped,

h. A constant water supply, draining system, and an aeration room.

9)How do I apply the clear coat?

Use a high quality clear coat to protect the decorated item.you can use matt ,satin,gloss finish or UV.The clear coat should be very durable to last over time and protect against scratches.

How do I dry my decorated parts?

After washing, the decorated items must dry out before applying the protective clear coat. This step can be accomplished with a heated room and circulating air, or just by normal air drying. Make sure the decorated item is completely dry before proceeding to the clear coating. Other options are thermal, flash drying and circulating air or blow drying

10)How is the film supplied?

All film comes in rolls 250sq.m (50 cm/100cm wide) for easy storage and production.

what temperature and humidity is it best to store the hydrographic film?

The hydrographic film is printed on polyvinyl alcohol (PVA) and it is very sensitive to humidity and temperature. You must store the film appropriately to ensure long life, durability and proper decorating. The hydrographic film must be stored in a humidity and temperature controlled room.Room humidity must be below 60% and room temperature between 20 and 25 degrees Celsius

11)How long does it take to create a custom hydrographic film?

Artwork is taken through the cylinder engraving process to produce the required film within 10-15days

12)Shipping Way

Express shiping: UPS/TNT/Fedex/DHL/EMS/TOLL,Normally need around 7 days delivery.

By Air & By Sea(Large Quantity)

- Harvesters 1 Pieces / (Min. Order)

- Peanut Harvester 1 Pieces / (Min. Order)

- Hybrid Inverters 1 Pieces / (Min. Order)

- Arresters 1 Pieces / (Min. Order)

- Hardener 1 Pieces / (Min. Order)

- Sargassum Harvester 1 Pieces / (Min. Order)

- 3/4" Harvester Bar 1 Pieces / (Min. Order)

- 404 Harvester Chain 1 Pieces / (Min. Order)

- 3/4 Harvester Chain 1 Pieces / (Min. Order)

- Harvester Bar Nose 1 Pieces / (Min. Order)

- Harvester Engine 1 Pieces / (Min. Order)

- Haynes 188 1 Pieces / (Min. Order)

- Haynes 25 1 Pieces / (Min. Order)

- Haynes 230 1 Pieces / (Min. Order)

- Haynes 556 1 Pieces / (Min. Order)

Menu

Menu

Favorites

Favorites

Frequent updates ensuring high quality data

Frequent updates ensuring high quality data

Over 5000 customers trust us to help grow their business!

Over 5000 customers trust us to help grow their business!

Menu

Menu